History :

Ion membrane alkali production is the most advanced alkali production process. The electrolytic cell in the alkali production process is the core equipment, and the ion membrane is the core material of the electrolytic cell In 2009, the mass production of Winocean chlor-alkali ion membrane and the trial of the 10,000-ton chlor-alkali plant brought about a huge conversion of production capacity. According to estimates, it could save 5.4 billion kWh of electricity, save 2.16 million tons of standard coal, and reduce carbon dioxide emissions at that time. 5.38 million tons. In 2010, with the official production of the membranes production plant, the price of imported membranes fell by more than 50%, and the 30-year history of China's chlor-alkali industry being controlled by others was completely rewritten.

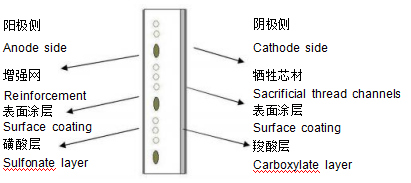

Structure:

Membranes for 30-34% NaOH production, with sacrificial thread channels, equipped with the most advanced technological feature.

Designed to work under higher current density with lower cell voltage and improved durability against brine impurities.

| Membranes | Tensile Strength(MPA) | Bursting Strength(MPA) | Tear Resistance(%) | Folding Strength |

| 2807 |

> 14 |

> 0.6 |

> 20 |

20-30 |

~2030

Membranes

Current Density(KA/M)

Cell Voltage(V)

Current Efficiency(%)

KWH/T NaOH

2807

4.5

2.9-3.0

> 97

Caution:

Place the membrane according to the “ANODE” sign and ensure the consistent of the membrane and the polar net surface of the cell.

As the core component in chlor-alkali industry. It is used to make NaOH or KOH, we can replace Nafion N2020, 2030 ,Aciplex F6801,F6807,F6808

Name: Michael Liu

Mobile:

Tel:

Email:info@pfsamembrane.com

Add: Polymer Material Industrial Zone,Zibo City,Shandong Province,China

We chat